- Alloy Cast Steel Base Adamite Rolls & Rings

- Graphitic / Graphitized Rolls & Rings

- S.G. (Nodular) Cast Iron Rolls

- Chilled Cast Iron Rolls

- Forged Steel Rolls, Shafts & Rings

- Steel Rolling Mill Equipments

- Steel & Iron Castings

Our Products

Contact Us Now

Indian Iron & Steel Industries

184/2, Sec-19/B, Jassran Road,

Vishwakarma Nagar,

Mandi Gobindgarh - 147 301,

Punjab, (India)

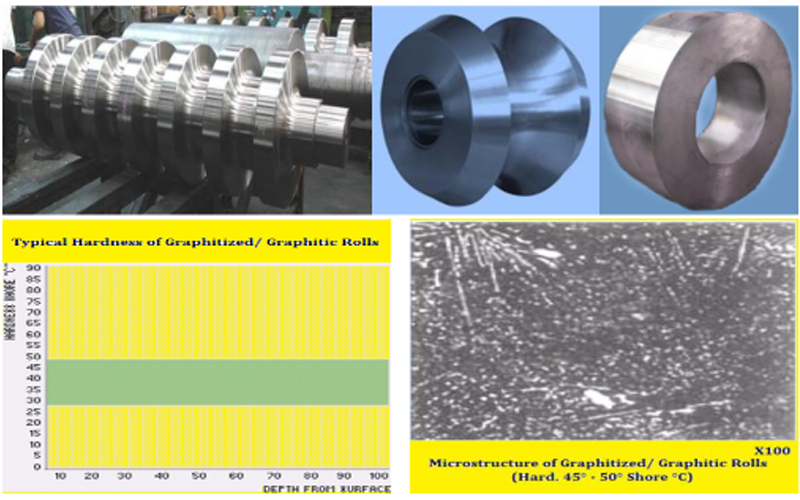

Graphitized Or Graphitic Rolls, Reels & Rings

Graphitic Steel Base Roll is similar to normal steel base but these rolls have the structure consists of Carbide in a Pearlitic matrix with free Graphite. Therefore, it is known as Graphitic Rolls. By modification of the alloy content and suitable heat treatment a controlled amount of fine graphite particles dispersed throughout the structure of the rolls are produced. These Rolls are greater than any other steel base Roll due to presence of the graphite improves the fire-crack resistance of the roll material and reduces thrust collar wear and the side wears which occurs during indirect heavy reduction

| Chemical Composition (Range) | Physical Properties | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C% | Mn% | Si% | Cr% | Ni% | Mo% | V% | S% | P% | Hardness Range (Shore 0C) |

Tensile Strength (N/mm2) |

Bending Resistance N/mm2) |

|||

| 1.20 2.50 |

0.70 1.25 |

0.60 2.00 |

1.00 2.00 |

0.80 2.50 |

0.20 0.80 |

0.10 0.60 |

0.040 Max | 0.045 Max | 400C - 600C | 500 – 800 | 850 – 1300 | |||

Product Application

Application of Graphitic Steel Base is very suitable according to Hardness & Chemical Composition range as per below:

| Rolling Mills | Mill - Type | Stands - Position | Pass - Condition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Heavy Section, Medium Section, Light Section, Beams, Rail & Bar Mills | 2 & 3 Hi or Universal | In all stands (Rough, Intermediate & Finish) | In case deep groove pass, Hireduction – ratio & Hi - thermal load | |||||||||

| Medium & Narrow Strip TMT & Wire load Rod Mills | 2 & 3 Hi | Only on Roughing Stand | ||||||||||

| Heavy, Medium & Light Section Mills | Can be used for Straightening Rollers (Reels) | |||||||||||